Technical Specifications

Product Overview

High-sensitivity seismometer for earthquake monitoring and structural response measurement.

Working Principle

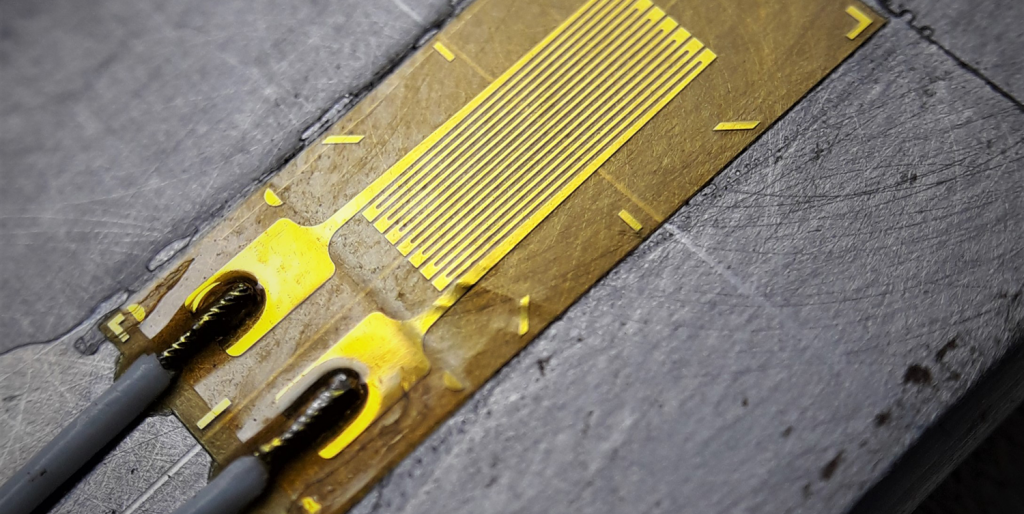

Accelerometer sensors employ piezoelectric or MEMS technology to convert mechanical acceleration into proportional electrical signals. Piezoelectric accelerometers utilize quartz or ceramic crystals that generate electrical charge when subjected to mechanical stress. MEMS accelerometers use microscopic silicon structures that change capacitance or resistance under acceleration. Both technologies provide wide frequency response and high sensitivity for vibration monitoring and shock measurement. Advanced signal conditioning electronics integrate charge amplification, filtering, and temperature compensation, delivering accurate measurements across a broad dynamic range.

Application Scenarios

Essential for machinery vibration monitoring, structural dynamics analysis, and condition-based maintenance programs. Widely deployed in rotating equipment monitoring, seismic instrumentation, vehicle testing, and aerospace applications. Critical for detecting bearing faults, imbalance, misalignment, and other mechanical defects before catastrophic failure occurs. The sensor supports predictive maintenance strategies, reducing unplanned downtime and maintenance costs. Applications span industries including manufacturing, power generation, transportation, and building monitoring.

Technical Advantages

Offers wide frequency response from sub-Hz to tens of kHz, covering both low-frequency structural dynamics and high-frequency machinery vibration. High sensitivity enables detection of subtle changes in vibration patterns indicating developing faults. Robust construction withstands harsh industrial environments including high temperatures, humidity, and corrosive atmospheres. Multiple mounting options including magnetic, stud, and adhesive methods provide installation flexibility. The sensor's self-generating output (piezoelectric) or low power consumption (MEMS) supports diverse application requirements.

Installation and Usage Guide

Select appropriate mounting method based on frequency range and measurement requirements. Stud mounting provides optimal frequency response for precision measurements. Magnetic mounting offers convenience for survey measurements and temporary installations. Ensure mounting surface is clean, flat, and rigid to maximize measurement accuracy. Orient the sensor to align the sensitive axis with the desired measurement direction. Connect to appropriate signal conditioning or data acquisition equipment. Verify installation by comparing measurements with known reference standards or baseline data.

Conclusion

The Seismometer SM-100 represents a reliable and accurate solution for demanding measurement applications. With proven performance across diverse industries and environments, this sensor delivers the precision and reliability required for critical monitoring and control applications. Our technical support team is available to assist with sensor selection, installation guidance, and troubleshooting to ensure optimal performance in your specific application.