Product Overview

Static stress-strain testing systems represent the foundation of materials testing and structural analysis. These precision instruments apply controlled static loads to specimens while measuring resulting deformations, enabling comprehensive characterization of mechanical properties including tensile strength, compressive strength, flexural properties, and elastic modulus. Bridgent Technology's static testing systems combine robust mechanical design with advanced measurement technology to deliver accurate, repeatable results across a wide range of testing applications.

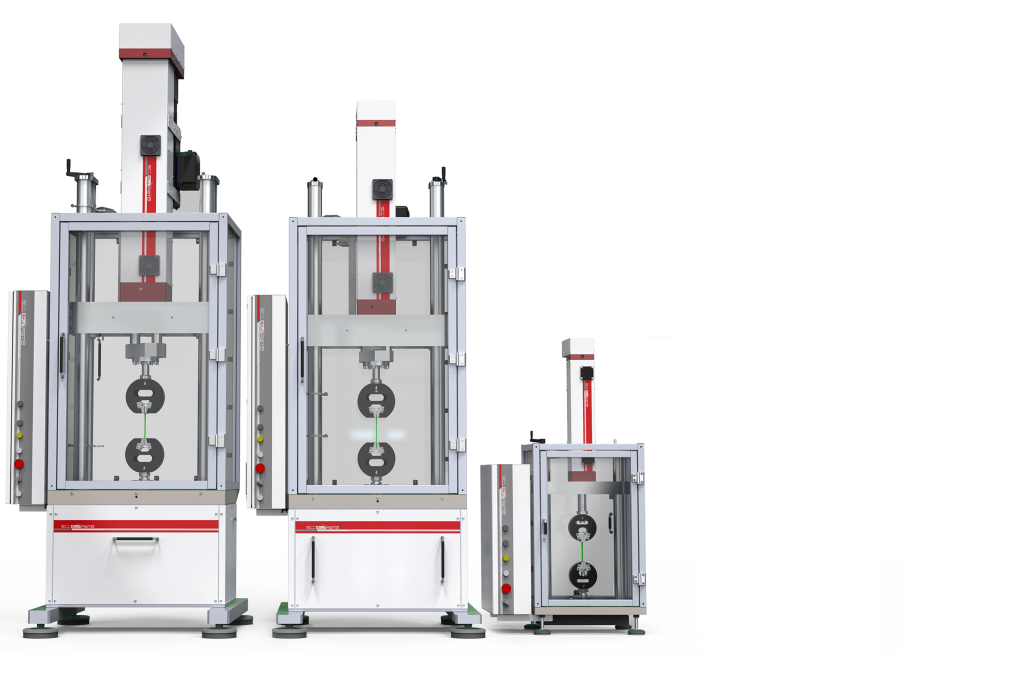

Our universal testing machines feature precision load frames with capacities ranging from small-scale laboratory instruments (5 kN) to large structural testing systems (5000 kN and beyond). Each system incorporates high-accuracy load cells, precision displacement transducers, and sophisticated control systems that enable both force-controlled and displacement-controlled testing modes. The modular design allows configuration with various grips, fixtures, and environmental chambers to accommodate diverse specimen types and testing standards.

Modern static testing systems integrate advanced data acquisition and analysis capabilities. Real-time stress-strain curve generation, automatic calculation of mechanical properties, and comprehensive test reporting streamline the testing process while ensuring data quality. Compliance with international testing standards (ISO, ASTM, EN, GB) is built into the system software, facilitating regulatory compliance and quality management system requirements.

- Material characterization and quality control testing

- Structural component validation and proof testing

- Research and development of new materials

- Failure analysis and forensic engineering

- Certification testing for regulatory compliance

Technical Specifications

5 kN to 5000 kN (1,000 lbf to 1,000,000 lbf) with multiple frame sizes available. Custom capacities for specialized applications.

±0.5% of indicated load from 2% to 100% of load cell capacity, meeting ISO 7500-1 Class 0.5 requirements.

0.001 mm (0.00004 in) with precision linear encoders. Optional extensometers for strain measurement to 0.1 µε.

0.001 to 500 mm/min (0.00004 to 20 in/min) with precise servo control. Programmable speed profiles for complex tests.

Force control, displacement control, strain control. Automatic switching between modes during test execution.

Up to 1000 Hz sampling rate, 24-bit resolution. Simultaneous acquisition of load, displacement, strain, and auxiliary channels.

Features & Benefits

Advanced servo-hydraulic or electromechanical actuators provide smooth, precise load application with minimal overshoot. Closed-loop control ensures accurate force or displacement tracking throughout the test.

Perform tensile, compression, flexure, shear, and peel tests with a single system. Quick-change fixtures and automated test sequences maximize productivity and testing flexibility.

Intuitive test control software with pre-programmed test methods for common standards. Real-time graphing, automatic calculations, and customizable reports streamline data analysis and documentation.

Multiple safety interlocks, emergency stop systems, and overload protection ensure operator safety. Robust construction and quality components deliver long-term reliability with minimal maintenance.

Complete static testing system with control console, data acquisition, and various testing fixtures

Industries Served

Static stress-strain testing systems serve diverse industries requiring precise mechanical property characterization. In aerospace and automotive sectors, these systems validate component strength and durability under design loads. Construction materials manufacturers rely on static testing for quality control of concrete, steel, composites, and other structural materials. Research institutions use these systems for fundamental materials science investigations and development of advanced materials with tailored properties.

Manufacturing industries employ static testing for incoming material inspection, process control, and finished product validation. Medical device manufacturers use specialized static testing systems to verify implant strength and surgical instrument performance. The packaging industry utilizes static testing to optimize container designs and ensure product protection during shipping and handling. Each application benefits from the precision, versatility, and reliability of modern static testing technology.