Product Overview

Dynamic signal acquisition systems capture and analyze time-varying signals from sensors monitoring vibration, shock, acoustic emissions, and other dynamic phenomena. These systems combine high-speed analog-to-digital conversion, anti-aliasing filters, and sophisticated signal processing algorithms to extract meaningful information from complex dynamic events. Bridgent Technology's dynamic acquisition systems offer sampling rates from 100 kHz to several MHz per channel, enabling accurate capture of high-frequency transients and detailed frequency domain analysis.

Modern dynamic signal analyzers integrate multiple measurement capabilities including FFT analysis, order tracking, modal analysis, and sound intensity mapping. Synchronous multi-channel acquisition with precise timing ensures accurate phase relationships between measurement points, essential for operational deflection shape analysis and transfer function measurements. Advanced triggering and pre-trigger capture capabilities ensure critical transient events are captured with sufficient context for analysis.

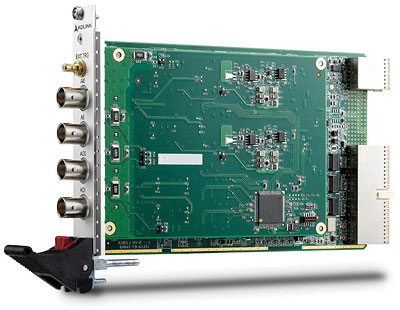

The systems feature flexible input conditioning with programmable gain, AC/DC coupling, and IEPE sensor excitation. Built-in calibration and sensor database management streamline setup and ensure measurement accuracy. Real-time processing capabilities enable immediate feedback during testing, while comprehensive post-processing tools support detailed analysis of recorded data.

- Vibration analysis and machinery diagnostics

- Modal testing and structural dynamics analysis

- Acoustic measurement and noise source identification

- Shock and transient event capture

- Rotating machinery analysis and balancing

Technical Specifications

100 kHz to 5 MHz per channel with simultaneous sampling across all channels. Anti-aliasing filters prevent frequency aliasing.

4 to 256 channels in modular configurations. Expandable systems for large-scale testing requirements.

120 dB or greater with 24-bit ADC resolution. Low-noise front-end amplifiers ensure accurate measurement of small signals.

DC to 100 kHz standard, extended ranges available. Configurable high-pass and low-pass filters.

IEPE, voltage, charge, bridge. Programmable excitation and signal conditioning for各种 sensor types.

FFT, power spectral density, transfer functions, coherence, order tracking, modal parameter extraction.

Features & Benefits

Advanced ADC technology and optimized data streaming enable capture of high-frequency phenomena without aliasing. Continuous recording modes support long-duration monitoring applications.

FPGA-based signal processing provides real-time FFT, filtering, and feature extraction. Immediate feedback accelerates testing and troubleshooting processes.

Complex trigger conditions based on signal level, frequency content, or external events. Pre-trigger and post-trigger capture ensures complete event documentation.

Integrated analysis tools for frequency domain, time domain, and order domain analysis. Export capabilities for further processing in specialized software packages.

Complete system configuration with advanced features and capabilities

Industries Served

Dynamic signal acquisition systems serve industries requiring detailed understanding of dynamic behavior. Automotive and aerospace manufacturers use these systems for NVH (noise, vibration, harshness) testing and structural dynamics validation. Power generation facilities employ dynamic monitoring for turbine vibration analysis and bearing condition assessment. Research institutions utilize these systems for experimental modal analysis and validation of finite element models. Manufacturing plants implement dynamic monitoring for predictive maintenance and quality control of rotating machinery.